Production

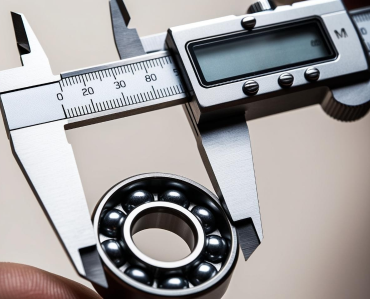

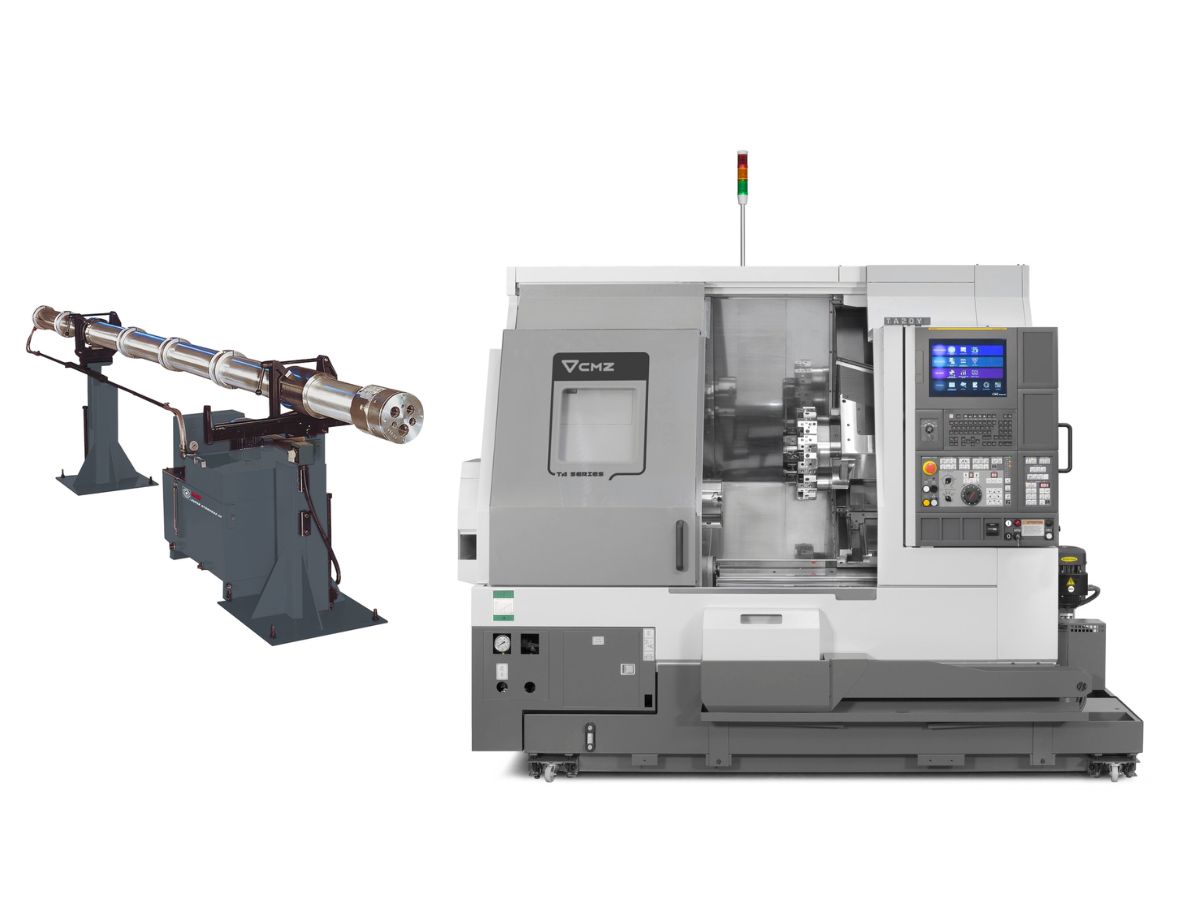

At EdgeTec, we specialize in the precise production of turned parts that meet the high demands of our customers across various industries. With modern turning machines and a skilled team, we are able to produce parts with high precision, excellent surface quality, and optimal dimensional tolerances.